Chinese Humanoid Robots Are Doing Factory Work: UBTech Partners with Foxconn for Smart Manufacturing

In a technological leap that's capturing global attention, China's robotics and AI sectors are pushing boundaries in ways that seemed impossible just months ago.

A surprising partnership between a major iPhone manufacturer and a robotics company is redefining factory automation.

Meanwhile, a small startup's humanoid robot has Silicon Valley's top minds questioning what's possible in robotics.

But China's ambitions stretch beyond just robots - the nation is rapidly building an AI infrastructure as a competition to the announced America's Stargate.

From affordable humanoid workers to computing power that rivals global leaders. But what exactly are these robots and AI developments for?

Let's explore the breakthroughs that are turning heads across the tech world.

Is This the Start of a Robot Revolution?

China's largest humanoid robot maker, UBTech Robotics, is taking a significant step by partnering with Foxconn, Apple's primary supplier, to integrate robots into factory operations.

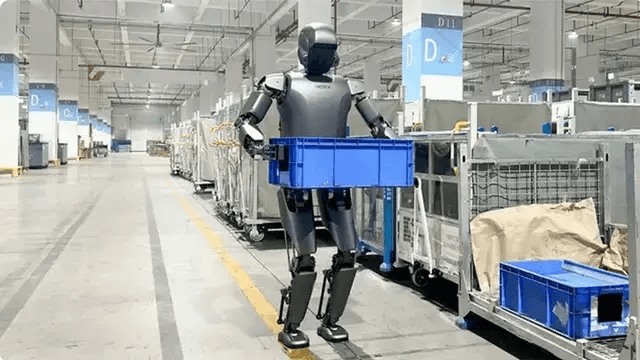

This collaboration marks a pivotal moment in manufacturing automation, as UBTech's Walker S1 robot has already completed logistics training at Foxconn's Shenzhen facilities.

The robots are being trained to handle complex manufacturing tasks, particularly in the 3C sector (computers, communications, and consumer electronics).

UBTech's Walker S1 robot is expanding its capabilities beyond basic movements to include:

Quality inspection of manufactured products

Sorting and organising factory materials

Material handling and transportation

Complex assembly line operations

Health-sensitive tasks to protect human workers

This partnership aims to revolutionise smart manufacturing by combining UBTech's robotics expertise with Foxconn's manufacturing experience. The collaboration includes developing a joint laboratory to advance robot capabilities in motion, perception, and decision-making.

What makes this partnership significant is UBTech's goal to achieve mass production of humanoid robots through Foxconn's established supply chain. This could lead to more affordable and widely available industrial robots, potentially transforming how factories operate in the future.

The initiative aligns with China's broader push toward industrial automation, where the country has already surpassed Germany and Japan in industrial robotics adoption.

Walker S1 Robot: The Robot Behind the Revolution

UBTech's Walker S1 robot stands out as the key player in this manufacturing transformation. The humanoid robot has already proven its capabilities during its two-month training period at Foxconn's Shenzhen facilities, preparing for deployment in various factory operations.

The Walker S1 demonstrates impressive versatility in handling essential factory tasks:

Advanced logistics operations in Foxconn's Longhua district

Movement of heavy materials between workstations

Precise sorting of manufacturing components

Quality control inspections using advanced sensors

Safe handling of delicate electronic components

The robot's success in Shenzhen has led to its upcoming deployment at Foxconn's car manufacturing facility in Zhengzhou. This expansion shows the robot's adaptability across different manufacturing environments, from electronics to automotive production.

Looking ahead, UBTech plans to launch the Walker S2 in the second quarter of 2025.

This upgraded version is expected to build upon S1's capabilities, though specific details haven't been revealed yet. The rapid development cycle from S1 to S2 indicates UBTech's commitment to continuous innovation in robotics technology.

The Walker series represents a significant step toward practical, everyday use of humanoid robots in manufacturing, moving beyond experimental phases to actual implementation in one of the world's largest manufacturing operations.

Behind the Headlines: The $5 Billion Question

Foxconn, Apple's major manufacturing partner, is strategically expanding from smartphones to electric vehicles, making its UBTech partnership crucial for future automation. This move signals a significant shift in how large-scale manufacturing will operate.

Key benefits of humanoid robots in factories:

Versatile operation across multiple production lines

Continuous operation without fatigue

Enhanced workplace safety in hazardous conditions

Reduced injury risks in demanding tasks

The financial aspects focus on two main areas:

Cost reduction through Foxconn's established supply chain

Improved efficiency in manufacturing operations

Through this partnership, UBTech aims to lower robot production costs while maintaining quality. The collaboration focuses on practical benefits: streamlined production processes, consistent quality control, and reduced operational costs.

This balance of investment versus long-term savings could reshape manufacturing economics, particularly in high-volume production environments like Foxconn's facilities.

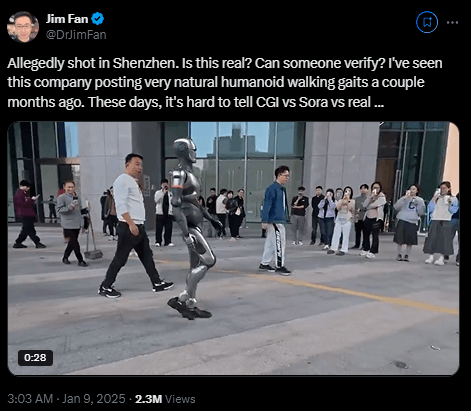

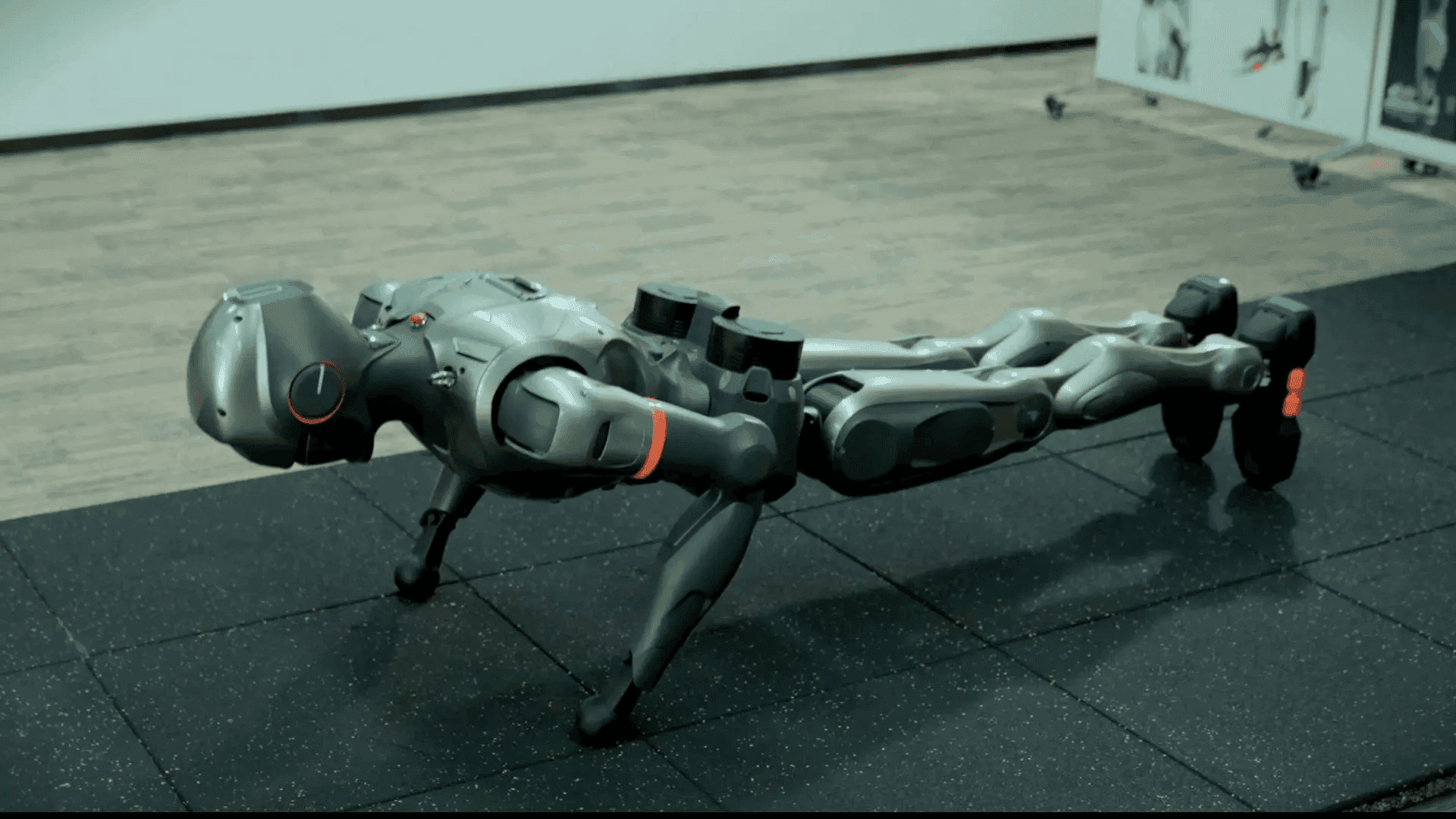

Viral Robot That Left Nvidia's Top Scientist Speechless

While UBTech and Foxconn's partnership makes headlines, another Chinese startup, Engine AI, is capturing global attention with its SE01 humanoid robot. A viral video of SE01 walking naturally in public caught the eye of Nvidia's senior scientist Jim Fan, who initially questioned if the footage was real.

The SE01's impressive capabilities include:

Human-like height at 170cm

Advanced mobility (walking, squats, push-ups)

Object manipulation skills

10-year operational lifespan

Industrial and home use applications

What's truly disrupting the market is Engine AI's aggressive pricing strategy:

Entry-level SA01 robot: $5,250

Mid-range PM01: $12,000

SE01 target price: $20,000-$27,000

Engine AI, founded in 2023 by former Xpeng robotics leader Zhao Tongyang, aims to make these robots commercially viable by keeping production costs under $14,000 per unit. This pricing strategy challenges competitors like UBTech, which is currently facing significant losses despite market leadership.

The company's rapid rise, backed by SenseTime's venture capital arm, shows China's growing influence in humanoid robotics, offering affordable alternatives to typically expensive industrial robots.

China's Race to Build Tomorrow's Workforce

China is rapidly emerging as a global leader in humanoid robotics, with companies like UBTech and Engine AI at the forefront. The recent partnership between UBTech and Foxconn, alongside Engine AI's viral SE01 robot, demonstrates China's commitment to revolutionizing manufacturing through automation.

Key developments shaping this transformation:

UBTech's Walker series integration into Foxconn's operations

Engine AI's affordable humanoid robots gaining global recognition

Focus on practical applications in manufacturing and logistics

Cost-effective production strategies to enable mass adoption

Also, China's technological advancement isn't limited to robotics; the nation is making significant strides in both AI infrastructure and deployment, too. In response to the US's $500 billion Stargate Project, China is accelerating its digital infrastructure development, particularly in high-performance computing facilities.

China is actively building new AI facilities, with local governments, telecommunications firms, and major tech companies involved in the development of approximately 250 advanced data centres across the country. This expansion aims to enhance China's computing power and capabilities in artificial intelligence, keeping pace with initiatives like Stargate1.

As of 2023, China's total computing power reached 230 exaflops, which measures the speed of computer systems. Although this figure indicates significant progress, it still places China behind the U.S. in terms of overall computing capacity

The strategy aims to overcome international restrictions while building self-sufficient technological capabilities, showing China's determination to compete in both physical automation and digital intelligence sectors.

Conclusion

China's technology and infrastructure is rapidly evolving with three major developments shaping its future. The groundbreaking partnership between UBTech Robotics and Foxconn in manufacturing automation, with Walker S1 robots already handling complex tasks in Foxconn's facilities. This collaboration aims to make humanoid robots more affordable and accessible through mass production.

Simultaneously, Engine AI has emerged as a disruptive force with its SE01 robot, gaining international recognition after impressing Nvidia's senior scientist. Their aggressive pricing strategy, offering advanced humanoid robots at a fraction of traditional costs, challenges industry norms and suggests a democratization of robotics technology.

Beyond physical automation, China is responding to the US's $500 billion Stargate Project by accelerating its AI infrastructure development. With 250 computing facilities under development and computing power reaching 230 exaflops, China is positioning itself as a formidable competitor in both robotics and AI sectors, despite international restrictions.

This shows China's commitment to leading the next industrial revolution through both physical automation and digital intelligence.

FAQs

1. How is China competing with the US Stargate Project's $500 billion investment in AI?

China has 250 computing facilities under development, reaching 230 eflops of computing power. The nation is accelerating infrastructure development to match US capabilities while focusing on efficient AI models that require fewer computing resources.

2. What makes the UBTech-Foxconn partnership significant for manufacturing?

The partnership combines UBTech's robotics expertise with Foxconn's manufacturing experience to mass-produce affordable humanoid robots. Walker S1 robots are already handling logistics, quality inspection, and complex assembly tasks in Foxconn's facilities.

3. Why is Engine AI's SE01 robot getting so much attention?

SE01 garnered attention for its natural walking abilities and competitive pricing ($20,000-$27,000). Its advanced capabilities, including human-like movements and 10-year lifespan, impressed even Nvidia's senior scientist Jim Fan.

4. What's the cost difference between traditional industrial robots and these new humanoid robots?

Engine AI's pricing strategy offers robots from $5,250 to $27,000, significantly lower than traditional industrial robots. They maintain low production costs under $14,000 per unit through efficient manufacturing processes.

5. How are these robots different from previous industrial robots?

These humanoid robots can handle multiple tasks across different production lines, from heavy lifting to delicate electronics handling. They offer 24/7 operation, advanced mobility, and adaptability between electronics and automotive manufacturing.

Comments

Your comment has been submitted